ROADBOND EN 1® is an eco-friendly soil stabilizer which is used to stabilize clay sub grade soil, strengthen and improve base material and enhance Portland cement and Flyash.

Roadbond EN1

BEST CHEMICAL SOIL STABILIZER

ROADBOND EN 1™ patented soil stabilizer fundamentally alters the ability of clay to hold adsorbed water, which is water held by electrical attraction. ROADBOND EN 1™ stabilizer causes clay to release weakly ionized water molecules from the clay matrix and replaces the water with strongly ionized sulfate radicals. The exchange is permanent and takes place at normal pH levels.

Roadbond EN1 saves water, saves energy and reduces Greenhouse gas emissions, whereas conventional stabilizers are high environmental impact products that are principally derived from the mining and calcination of limestone. The benefits of Roadbond are:

- More Compaction & Density

- Smaller Project Carbon Footprint

- Greater Triaxial Strength

- Reduced swelling in Clay soils

- Longer Durability

- Increased Load bearing capacity

CALIFORNIA BEARING RATIO IMPACT

Since 1986, Roadbond EN1, has consistently exhibited superior enhancement of CBR values of the subgrade over a period of time.

- Stabilize clay subgrade soil

- Maximize Portland cement & flyash

- Strengthen base material & recycled in-place material

- Increases strength & load-bearing capacity

- Reduces permeability

- Increases dry weight

- Open to traffic end of the day

- Saves time and money

- Reduces repair & maintenance

- Installs quickly

- Density on day 1

- No need to remix

- Often paved in less than 5 days

- Strength improves over time

- No sulfate reaction problems

- Lowers Carbon Footprint Of The Project

- Green manufacturing

- Primary component – recovered / recycled

- Redirected from waste stream

- Secondary component – renewable resource

VARIOUS USES OF ROADBOND EN1

REPLACE – ROADBOND EN 1™ is used in lieu of lime to stabilize clay subgrade soils. The advantages over lime include reduced water use, energy consumption, and CO2 emissions. It is also placed, mixed, compacted, and finished in one operation without the need to remix. Many projects are placed and paved in less than 5 days!

REDUCE – ROADBOND EN 1™ is used to enhance the effectiveness of conventional stabilizers such as Portland cement and fly ash. This means the amount of conventional stabilizer can be reduced by 40% to 50% without a corresponding drop in strength.

VARIOUS USES OF ROADBOND EN1

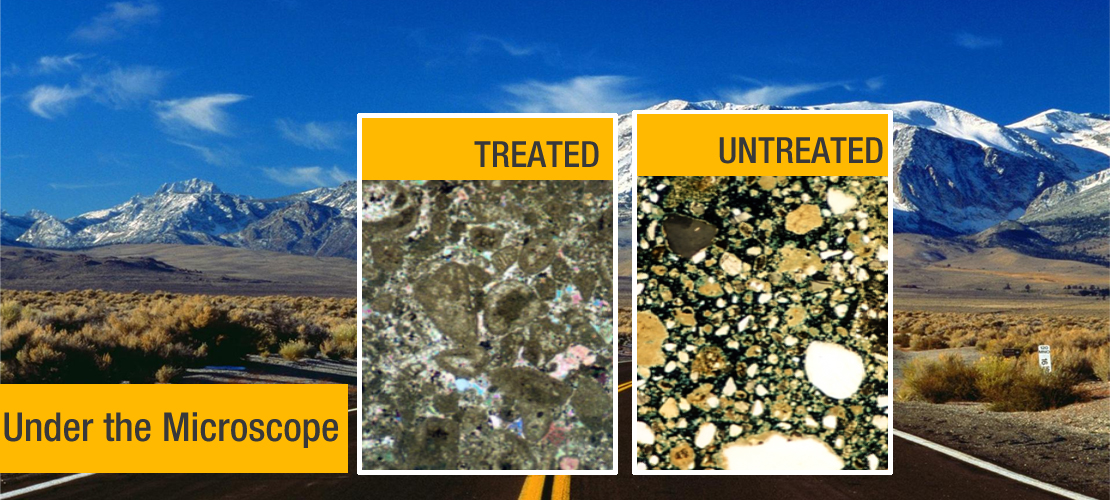

REINFORCE – ROADBOND EN 1™ improves the strength of base material and recycled in-place material. Field trials and lab tests confirm that soil treated with ROADBOND EN 1™ is significantly stronger than untreated material and that the strength improves over time.

REMEDIATE – ROADBOND EN 1™ patented soil stabilizer is used to encapsulate and confine oil base drill cuttings to provide long-term prevention of leaching of heavy metals and petroleum hydrocarbons into the environment. This is an economical, on-site or near-the-site process for treating these heavily contaminated drill cuttings.